Technological innovation

Study on Preparation of Reductive Iron Powder from Ferrous Sulfate

Study on Preparation of Reductive Iron Powder from Ferrous Sulfate

Seven water ferrous sulfate, also known as green alum, is the production of titanium by-product, each production 1t titanium dioxide output green alum 2.5 ~ 4t, green alum itself is a cheap iron resources, therefore, comprehensive utilization of green alum is both There are good economic benefits and good social benefits.

The use of pyrite sulfuric acid slag preparation of sponge iron SIO2 and other impurities due to high content, is not conducive to the preparation of reduced iron powder. But with sulfuric acid out of the slag, in the use of mechanically activated pyrite reduction can be made cheaper than the pure chemical standard of ferrous sulfate, ferrous sulfate prepared by the reduction of iron or the reduction of the solution directly after the preparation of reduced iron Powder, it will expand the comprehensive utilization of pyrite cinder path.

It is advisable to prepare the reduced iron powder with ferrous sulfate and pyrite slag, but there are a few key steps in the preparation of the firing that need to be taken into account and controlled. Here's our key point for these process control Make the following description:

1. The process of preparing the reduced iron powder from the green alum is: the green alum is converted into FeCO3 by (NH4) 2CO3, then the crude reduced iron powder is obtained by reduction calcination with anthracite, and then the reduced iron powder is prepared by secondary reduction of hydrogen The This provides a new path for the comprehensive utilization of ferrous sulphate slag and titanium dioxide by-product.

2. FeCO3 is used as reducing agent, anthracite as reducing agent, CaCO3 is desulfurizer and catalyst, the best technological condition is FeCO3: coal: CaCO3 bit 100: 60: 8, with concentric ring or layered The calcined temperature is 1000C and the calcination time is 4.5h. The crude iron reduction is in accordance with the relevant national standard of the reduced iron powder except for the C content.

3. Reduction of iron powder in about 900C by H2 reduction, can further improve the total iron content and metallization rate of iron powder, significantly reduce the iron content of C, S content is also slightly reduced, so that the secondary reduction of iron powder Relevant national standards.

We have talked about the previous sulfuric acid titanium dioxide reduction iron powder in the middle of the application, titanium dioxide by-product ferrous sulfate can also be made of reduced iron powder, we can see the reduction of iron in the titanium industry which can be recycled, and the use of Big.

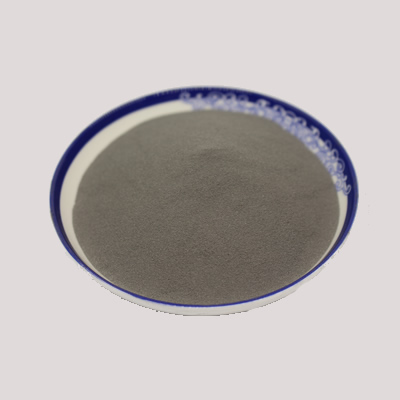

Reduction of iron powder is an important raw material for the powder metallurgy industry, whether it is manufacturing machinery parts, or the production of friction materials, wear materials, superhard materials and magnetic materials are used in chemical production is also widely used as a reducing agent, reagents And catalyst equipment, but also used in electrode manufacturing, flame cutting and wastewater treatment and so on. The use of green alum to produce reduced iron powder is an effective way for the comprehensive utilization of green alum.

Categories

Latest News

- mild steel iron powder, Mild Seel Iro Powder: A Comprehesive Overview2024-04-09

- magnetite and iron powder,The Properies of Mageie2024-04-09

- iron dust for sale, high quality iron powder for sale2024-04-09

- carbonyl iron powder, Introduce carboyl iro powder2024-04-02

- iron oxide powder pigment, What is iron oxide powder pigment?2024-04-02

Contact Us

Contact: Ms.Anna Fei

Phone: +86-15036079565

Tel: +86-371-64368520

Email: info@meiqicn.com

Add:BEISHANKOU TOWN, GONGYI CITY, HENAN, CHINA 451200