Company news

Method for preparing thermal decomposition and electrolysis of carbonyl iron powder

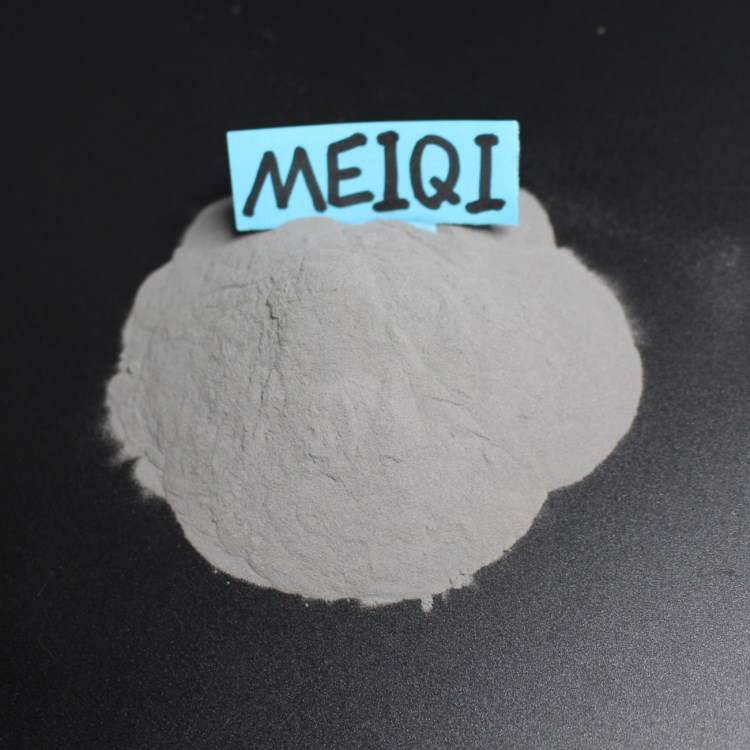

Carbonyl iron powder - uncoated iron powder, by thermal decomposition of iron pentacarbonyl iron, reacts with iron powder under pressure to form iron pentacarbonyl, Fe(CO)5, and purifies iron pentacarbonyl by distillation (residual metal is usually <10 ppm). The purified iron pentacarbonyl is evaporated by heating and decomposed into carbonyl iron powder and carbon oxide, and during the decomposition process, iron particles grow on the core to form spherical iron particles.

This method achieves properties (chemical composition, particle shape and distribution) unmatched by water atomization or gas atomization processes. Typical sizes of carbonyl iron powders range from <1 to 8 microns (primary particles). Pig iron powder grades can be sent to finishing operations for other applications such as milling, grading, mixing and coating.

Electrolytic production is another method of batching iron powder. The anode is usually made of iron or low carbon steel. The electrolyte of the battery is composed of a sulfate solution (temperature 50 ° C), and the pure iron is deposited on the cathode as a brittle slightly sticky. Attached, after washing, drying and stripping, the deposited iron is ground, further ground and annealed to meet the requirements of a particular application.

Categories

Latest News

- mild steel iron powder, Mild Seel Iro Powder: A Comprehesive Overview2024-04-09

- magnetite and iron powder,The Properies of Mageie2024-04-09

- iron dust for sale, high quality iron powder for sale2024-04-09

- carbonyl iron powder, Introduce carboyl iro powder2024-04-02

- iron oxide powder pigment, What is iron oxide powder pigment?2024-04-02

Contact Us

Contact: Ms.Anna Fei

Phone: +86-15036079565

Tel: +86-371-64368520

Email: info@meiqicn.com

Add:BEISHANKOU TOWN, GONGYI CITY, HENAN, CHINA 451200