Industry news

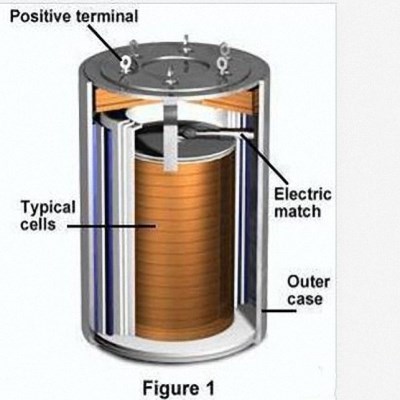

The application of reduced iron powder in hot battery

Early thermal battery heating source USES a heating system of Zr/BaCrO4 paper, but its sintering conductive performance is poor, with high resistance contact between electrode and collection of fluid, plus line, at the same time the system static sensitive, in a large number of potential dangers exist in the process of production.

With the development and effort of scientific research workers in the later stage, the target is locked in Fe/KClO4 system heating.

The heating plate of the system is composed of 80%-88% fine iron powder and KClO4 mixture. Excessive iron powder ensures good conductivity of the heating plate after combustion, and realizes the low resistance contact of the electrode and the set fluid.

At present, the heating paper is used only as a flash point and a heating envelope in a new type of heating film.

In this case the ignition strip is ignited by the ignition head, and then the ignition strips are ignited in turn, and the heating plate is the main heating source of the thermal battery.

Due to their small size, reduced iron powder, the advantages of high specific surface area and good chemical activity, have a higher combustion rate and lower ignition energy (or detonate the required minimum ignition energy), to a smaller, ignition and rapidly melting electrolyte voltage can shorten the thermal battery discharge reaction time.

Categories

Latest News

- mild steel iron powder, Mild Seel Iro Powder: A Comprehesive Overview2024-04-09

- magnetite and iron powder,The Properies of Mageie2024-04-09

- iron dust for sale, high quality iron powder for sale2024-04-09

- carbonyl iron powder, Introduce carboyl iro powder2024-04-02

- iron oxide powder pigment, What is iron oxide powder pigment?2024-04-02

Contact Us

Contact: Ms.Anna Fei

Phone: +86-15036079565

Tel: +86-371-64368520

Email: info@meiqicn.com

Add:BEISHANKOU TOWN, GONGYI CITY, HENAN, CHINA 451200