Industry news

Reduced iron powder application for aluminum alloy iron additive

The role of iron in aluminum alloy:

Iron in Al - Cu - Mg - Ni - Fe in the forging of aluminum alloy, silicon in Al - Mg - Si is wrought aluminium and in Al - Si electrode and aluminum silicon alloy casting, all of the alloy elements and in the aluminum alloy, silicon and iron is a common impurity elements, have obvious influence on performance of alloy.

They mainly exist in FeCl3 and free silicon.

When silicon is greater than iron, it forms beta-fesial3 (or Fe2Si2Al9), while iron is greater than silicon to form alpha-fe2sial8 (or Fe3Si2Al12).

When the ratio of iron and silicon is not at that time, it will cause the casting to crack, and the iron content in the cast aluminum will make the casting brittle.

The effect of adding iron for aluminum alloy:

Aluminum alloy additive, also known as aluminum alloy flux;

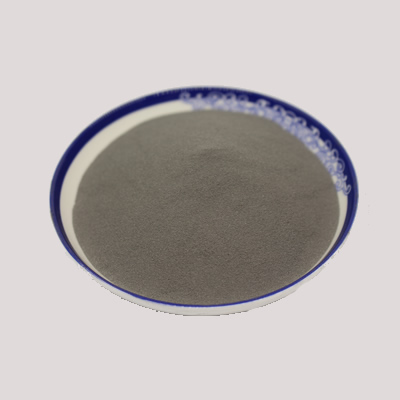

This product is a grey powder additive, which is used to adjust the content of iron elements in different brands of aluminum alloy, which can be used to replace the intermediate alloy and reduce the melting temperature.

It can simplify the melting process of aluminum alloy, save energy and raw materials, reduce production cost, improve product quality, and have high metal content, small volume, convenient for storage and transportation, etc.

Have the following advantages:

1. The actual yield of this product is over 90%

2. Low temperature rapid melting

3. Convenient storage and easy to use

Usage:

1. When the aluminum melts, mix the aluminum liquid evenly, and the temperature will be even

2. Measure aluminum liquid temperature in 720 ℃ + 10 ℃

3. After reaching the temperature, remove the scum and input the required amount of additives

4. Stand still for 10 minutes, stirring evenly for 5 minutes, and then static for 5 minutes for sampling and testing

5. After refining the scum, it can be cast

Our company is specialized in the production of aluminum alloy iron powder and potassium cryolite, with unique aluminum alloy additive technology, the product reaches the domestic advanced level;

It can be processed according to the customer's demand, all products are inspected and qualified, and the iron casting agent is dissolved in 2~5 minutes after casting, and the absorption rate is greater than 90%!

Categories

Latest News

- mild steel iron powder, Mild Seel Iro Powder: A Comprehesive Overview2024-04-09

- magnetite and iron powder,The Properies of Mageie2024-04-09

- iron dust for sale, high quality iron powder for sale2024-04-09

- carbonyl iron powder, Introduce carboyl iro powder2024-04-02

- iron oxide powder pigment, What is iron oxide powder pigment?2024-04-02

Contact Us

Contact: Ms.Anna Fei

Phone: +86-15036079565

Tel: +86-371-64368520

Email: info@meiqicn.com

Add:BEISHANKOU TOWN, GONGYI CITY, HENAN, CHINA 451200